The chemical industry involves the industrial sector that utilizes chemical processes and equipment to produce chemicals, petroleum products, pharmaceuticals, food, and other products. In the chemical industry, piping systems are vital components used to transport fluids such as liquids, gases and solid particles. These piping systems must be able to withstand corrosion from chemicals, withstand high pressures and temperatures, maintain stable operation over long periods of time, and maintain a high degree of operational safety. Therefore, when selecting and designing a pipeline system, factors such as the nature of the medium, working conditions (temperature, pressure, etc.), pipeline layout, safety requirements, and economy need to be comprehensively considered to ensure the performance and reliability of the pipeline system.

PVDF Pipe, which stands for Polyvinylidene Fluoride tubing, is a high-performance plastic piping material that has gained widespread application due to its unique physical and chemical properties. This type of piping material is highly praised for its exceptional chemical corrosion resistance, whether it is exposed to strong acids, strong bases, or other corrosive media, PVDF Pipe can demonstrate resistance capabilities, ensuring the long-term stable operation of the piping system. In addition to its outstanding corrosion resistance, PVDF Pipe also has high mechanical strength. Its tensile strength and flexural strength are both very high, capable of withstanding significant pressure and external forces, ensuring the safe use of the pipe in various complex working environments.

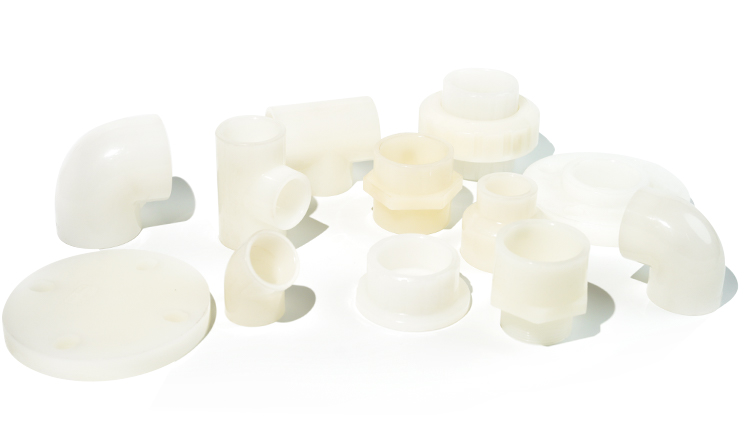

As a PVDF pipe manufacturer, huadaplastics is committed to providing exceptional products that not only meet but exceed the stringent demands of a wide range of industrial sectors. We prioritize innovation and quality control throughout the manufacturing process, ensuring that every pipe we produce offers unparalleled durability, chemical resistance, and mechanical strength.

English

English 中文简体

中文简体 русский

русский عربى

عربى