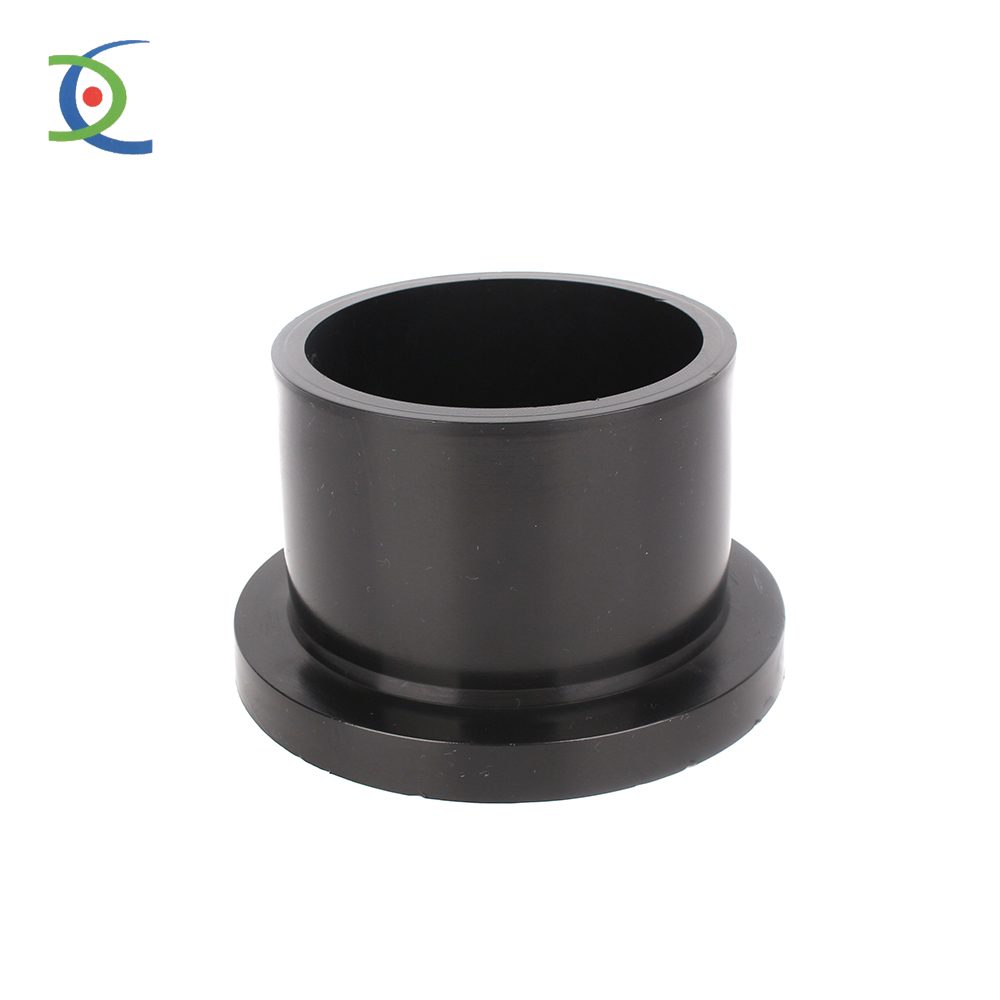

In the field of fluid pipeline systems and related equipment, various specialized components play a crucial role in ensuring the operational performance of the system. One such component is the short pipe end, a device often overlooked but playing a key role in fluid pipeline systems. However, what exactly is the function of the short pipe end? This article will elaborate on the functions and importance of the short pipe end in fluid pipeline systems.

The short pipe end is typically placed at the end of the pipeline or pipe material and is precut or sealed before installation. During the actual installation process, these short pipe ends are often in an unconnected state, also referred to as a "stub end," awaiting further connections or assembly. These short stub ends serve several crucial functions.

Firstly, the short stub end provides an access point for subsequent connections. Whether connecting to other pipelines, fittings, or valves, the short pipe end facilitates easy and convenient connections during the installation process, favored for its flexibility and ease of assembly.

Secondly, the short stub end protects the end of the pipeline from damage during installation and transportation. By maintaining the end unconnected to other parts, the short pipe end acts as a shock absorber, preventing damage to the pipeline itself. This design is particularly meaningful for fragile pipelines or those made of vulnerable materials.

Thirdly, the short pipe end can serve as a base for supporting structures or brackets. In certain situations, additional support may be required due to the weight of the pipeline or the back-end stresses during operation. During installation, by keeping one end of the pipeline unconnected, it can easily be connected to the supporting structure after the equipment is in place.

In addition to the mentioned applications, the short pipe end also plays a role in the design and planning of fluid pipeline systems. During the design phase, engineers and installers invest significant effort in considering how to utilize short pipe ends to enhance installation and assembly efficiency. This often involves determining the optimal placement of short stub ends, ensuring smooth future connections, and maintenance.

It is crucial to emphasize that safety should always be a top priority when using short pipe ends. Properly securing and sealing the short pipe end to prevent foreign objects from entering the system and causing blockages or damage is of paramount importance. Appropriate fittings and seals should be used to ensure the system remains airtight and watertight.

In conclusion, the short pipe end plays a crucial role in fluid pipelines and pipeline systems, serving as both an access point for connections and a protective measure for the end of the pipeline. Understanding its applications and using it correctly are essential for ensuring the functionality and durability of any fluid pipeline system. Whether you are an engineer, a pipeline worker, or someone seeking a deeper understanding of the operational mechanisms of fluid pipeline systems, a comprehensive understanding of the role of the short pipe end and its contribution to the overall operation of the fluid pipeline system is essential.

Post time: Jan-26-2024