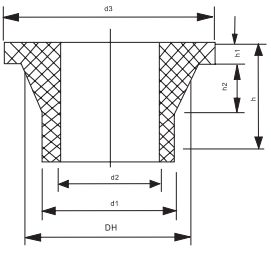

PVDF Looper Flange

Name: PVDF Looper Flange

Material: PVDF (100% virgin material)

Pressure level: 0.6MPa ,1.0MPa

Jointing: Threading

Color: White

Standards: ISO10931

Brand: New Golden Ocean

Origin: Jiangsu, China

Density: 1.17~1.79gcm3,

Melting point: 172℃

Long-term working ambient temperature range: -40~150℃

Thermal deformation temperature: 112~145℃

Oxygen index: 46%

Crystallinity: 65%~78%

1.Superior Material Performance:

Jiangyin Huada’s PVDF Looper Flange harnesses the exceptional properties of this polymer, including high-temperature resistance, chemical corrosion resistance, excellent electrical insulation, and anti-aging characteristics, ensuring reliable and durable performance.

2.Flexible and Adjustable Design:

Featuring a unique looper design, this kind of flange allows for precise alignment and easy adjustment during installation. This enhances connection flexibility, making it adaptable to changes in the pipeline system and simplifying installation processes.

3.High Pressure and Corrosion Resistance:

Jiangyin Huada’s PVDF Looper Flange exhibits high-pressure resistance and robust corrosion resistance. It withstands various chemical mediums, including acids, alkalis, solvents, ensuring longevity and reliability in fluid transport applications.

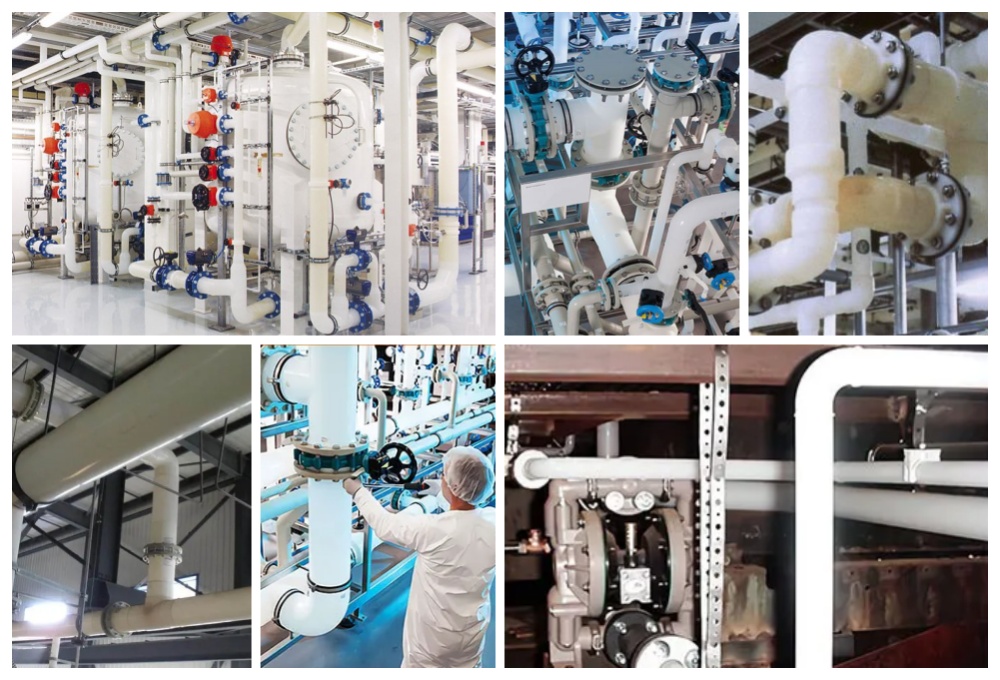

4. Wide Application Range:

With its adaptability and adjustability, our PVDF Looper Flange finds wide application across industries such as chemical, pharmaceutical, and semiconductor manufacturing. It is an ideal choice for diverse pipeline system requirements, showcasing its versatility.

1. Chemical engineering: used to transport corrosive chemicals such as acids, alkalis, solvents and oxidants

2. Semiconductor manufacturing: used to transport high-purity chemicals and corrosive gases

3. Water treatment: used in water supply and wastewater treatment fields, including the transportation of corrosive chemical reagents, gases and drinking water

4. Mining and metallurgy: used to transport acidic and alkaline slurries, chemical reagents and high-temperature liquids

5. Sanitary engineering: used to transport high-purity water, medicines and food, such as pharmaceuticals and food processing

6. Electroplating industry: used to transport acidic and alkaline solutions and various electroplating chemicals

Incoterms: EXW, FOB, CRF, CIF

Packing: Standard export wooden case, Carton, or as your request

Starting Port: Port of Shanghai or as your request

Lead time: 15-30 days after confirming the order

Transportation method: Sea, Railway, Air, Express delivery, etc.