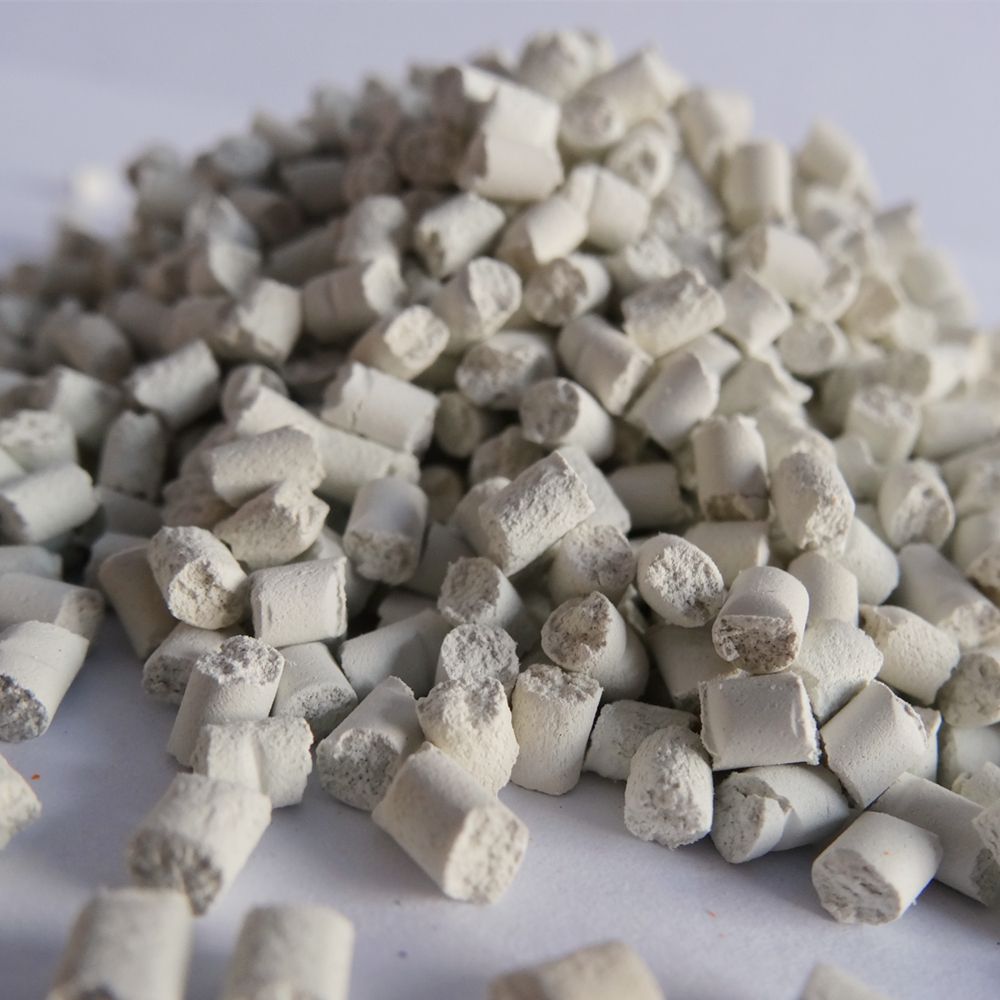

White Masterbatch

Name:White Masterbatch

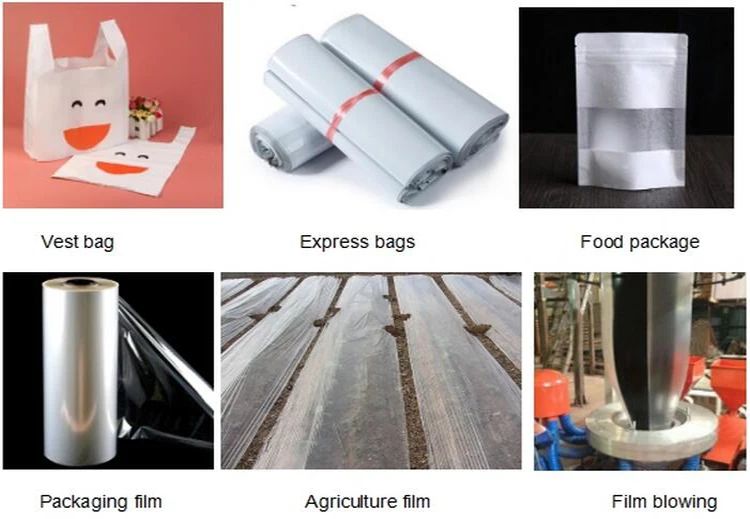

Usage:Plastic products production

Color:White

Certifications:SGS report,ISO9001,ISO45001,ISO14001,MSDS report

Brand:Huada

Origin:Jiangsu,China

| Product type | Carrier | Applications | Markets |

| 70%Tio2 | PE,PP,TPU | Film,Injection Moulding, Extrusion Moulding |

Pakaging,consumer goods,construction, agriculture,appliances,automotive |

| 60%Tio2 | PE,PP | Film,Injection Moulding, Extrusion Moulding |

Pakaging,consumer goods,construction, agriculture,appliances,automotive |

| 50%Tio2 | PE,PP | Film,Injection Moulding, Extrusion Moulding |

Pakaging,consumer goods,construction, agriculture,appliances,automotive |

| 40%Tio2 | PE,PP | Film,Injection Moulding, Extrusion Moulding |

Pakaging,consumer goods,construction, agriculture,appliances,automotive |

| 30%Tio2 | PE,PP | Film,Injection Moulding, Extrusion Moulding |

Pakaging,consumer goods,construction, agriculture,appliances,automotive |

1. Optimal Color Coverage:

White Masterbatch, enriched with titanium dioxide, ensures outstanding color coverage, effectively concealing the substrate's original color and enhancing the vibrancy of the end product.

2. Excellent Dispersion:

Typically processed with surface treatments, the White Masterbatch particles exhibit excellent dispersion within the resin matrix. This promotes uniform pigment distribution, preventing color inconsistencies or spotting in the final product.

3. Weather Resistance:

White Masterbatch offers superior weather resistance, effectively countering the impact of UV rays and environmental factors. This ensures color stability and longevity, preserving the product's appearance even in challenging conditions.

4. Versatility Across Resins:

White masterbatch is often compatible with a range of plastic resins, including polyethylene (PE), polypropylene (PP),etc. This versatility allows for broad application in diverse plastic manufacturing processes.

5. Environmental Considerations:

Some white masterbatch products are designed with environmental considerations in mind, incorporating components that meet sustainability standards. This aligns with current societal demands for eco-friendly and sustainable practices in manufacturing.

Inco-terms: EXW, FOB, CRF, CIF

Packing: Woven bag(25kg/bag) or as your request

Staring Port: Port of Shanghai or as your request

Lead time: 15-30 days after confirming the order

Transportation method: Sea, Railway, Air, Express delivery, etc.