During the 2022 Qatar World Cup, in order to meet the accommodation needs of a large number of tourists, the organizers built a large group of tent hotels in the desert. One of the core challenges of this temporary accommodation project is how to achieve stable and safe water supply in extreme climates (high temperature, wind and sand). This article will focus on the water supply pipe system of this project, including material selection, design optimization and technological innovation.

Content

1. Project Background and Water Supply Challenges

(1) Environmental Characteristics

High temperature and dryness: Daytime temperatures can reach 45°C, accelerating pipe aging.

Sandstorms: Wind and sand can easily clog pipes or wear joints.

Temporary Requirements: Quick installation and disassembly are required, and zero failures during the game are guaranteed.

(2) Water Supply Scale

Coverage: More than 10,000 tents, with an average daily water supply of approximately 5,000 cubic meters.

Water Quality Requirements: Meet WHO drinking water standards and prevent microbial growth.

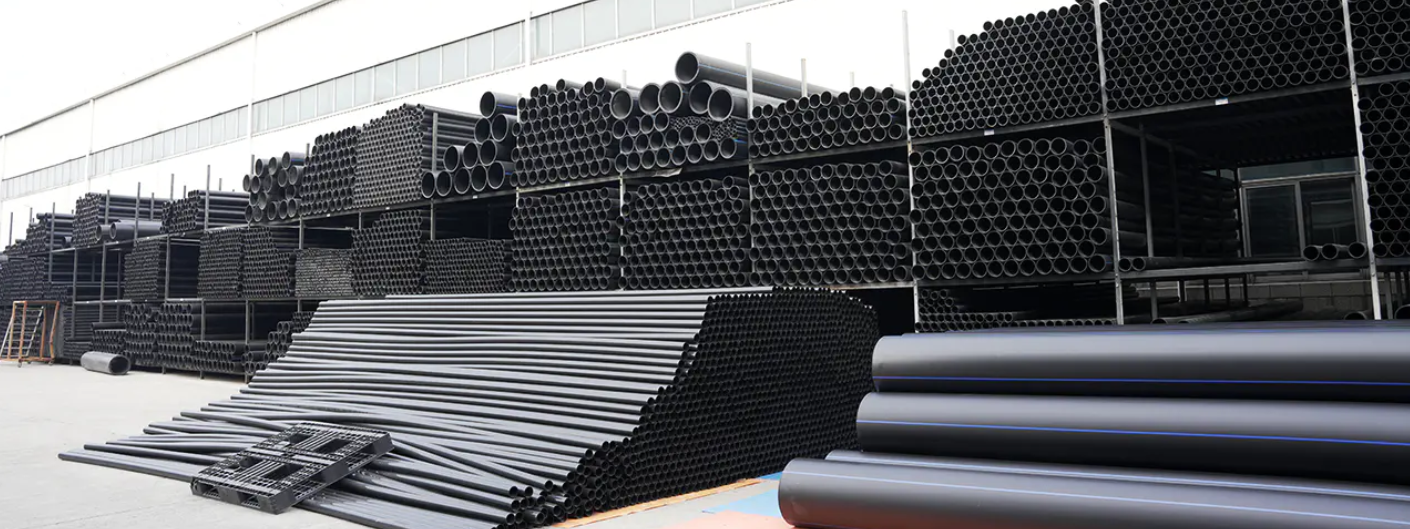

2. Pipe Selection and Material Innovation

(1) Core Pipe Selection

| Pipe Fitting Type | Material | Advantages | Applications |

| Main water supply pipes | HDPE (High-Density Polyethylene) | High-temperature resistant (-50°C to 60°C), UV-resistant | Underground and surface pipes |

| Branch connection pipes | PPR (Polypropylene Random Copolymer) | Leak-proof, corrosion-resistant hot-melt connection | Tent internal water distribution pipes |

| Quick connectors | 304 stainless steel quick-release clamps | Instant disassembly and assembly, dust-resistant | Temporary pipeline connections |

(2) Key technological innovations

UV-resistant coating: A carbon black layer is added to the outer wall of HDPE pipes to delay sunlight aging.

Modular design: Prefabricated pipe sections + quick-release connectors increase installation efficiency by 60%.

Intelligent monitoring: A built-in flow sensor detects leaks and water quality (pH, turbidity) in real time.

3. Construction and Operation and Maintenance Management

(1) Fast Installation Process

Prefabricated Production: 70% of the components are pre-installed in the pipe fitting factory, and only splicing is required on site.

Non-excavation Technology: Directional drilling is used to lay the main pipeline in the desert area to protect the ecology.

Pressure Testing: All pipelines are pressure tested at 1.5 times the working pressure and maintained for 30 minutes.

(2) Post-Games Demolition and Recycling

Material Recovery Rate > 90%: HDPE pipes can be melted and recycled, and stainless steel parts can be reused.

Ecological Restoration: After removing the pipeline, the sand is backfilled and no chemical pollution remains.

English

English 中文简体

中文简体 русский

русский عربى

عربى